In a Job Shop Scheduling Software, you need specific algorithms and logic for sequencing tasks in a Job Shop manufacturing.

A Job Shop Scheduling tool defines ways to handle the underlying work structure and principal concepts of job shop manufacturing which are apart from line production.

This guide looks at the needs of repair and overhaul industries when it comes to job scheduling and gives examples of job shop scheduling features for repair and overhaul industries.

Basic Requirements

Most decent Job Scheduling Software does the basic production scheduling and provides some features for shop scheduling.

Some features are about working with the software itself, and you should consider them as options, not as decision influencers.

On the other hand, there are features that set apart a job shop scheduling software to fit and work for a Job Shop. These features should be the focus of decision-making.

To get a quick review you can also check the top 10 features in Manufacturing Scheduling Software, which you should know for a successful implementation.

What are the types of job shop manufacturing?

- Job Shops with Unique Jobs:

Each job shop production has its own production variables that make it a job shop. The logic and algorithms used in scheduling for a job shop production closely depend on its manufacturing variables.

- Job Shops with Different Batch Sizes:

Some job shop productions are about small batch size, some others are about custom manufacturing, and some are one of a kind with a quantity of one, every time. Here you can find a detailed article about different job shop manufacturing, maintenance, repair, and overhaul services.

What are the challenges in Job Shop Scheduling?

When it comes to manufacturing, not all Job scheduling tools work the same, some are a better fit, and some are a better tool. Features like user-friendly interface, interactive environment, and fancy colorful gadgets are all about the generic functionalities and look of the software.

Versus features like recognition of disassembly operation, planning for long-lead-time components, or considering subcontract services are fundamental for a successful job shop scheduling Software.

Finding the right Job Shop Scheduling Software

In manufacturing, production line scheduling is different than job shop scheduling. Usually, a production line is set for the continual production of one product while in a job shop, configuration or quantities vary a lot. Here are some of the main characteristics that differentiate Job Shop Scheduling as below:

- Shop vs Job Shop: All job shops are a shop, but not all shops can be described as a job shop. A job shop operates fundamentally differently than a shop. This depends on the type of jobs and their sequence. For instance, a job shop might need to have flexible scheduling due to the unpredictable nature of some jobs.

- Scheduling vs Job Scheduling:All job scheduling tools are scheduling tools, but not all scheduling tools are necessarily job scheduling tools. Even a calendar is a tool for scheduling yet it is not necessarily a job scheduling tool.

- Shop Scheduling vs Job Shop Scheduling: Some job shop scheduling tools may do shop scheduling, but no shop scheduling tool can do job shop scheduling. To read

Understanding the need and requirements of your job shop is the first step in adopting a successful job shop scheduling software.

Manufacturing businesses are different and have their unique processes in place. The right job shop scheduling products with the right features can immensely optimize the production workflow. Consequently, having the right features in a job shop scheduling software determines its success in the implementation.

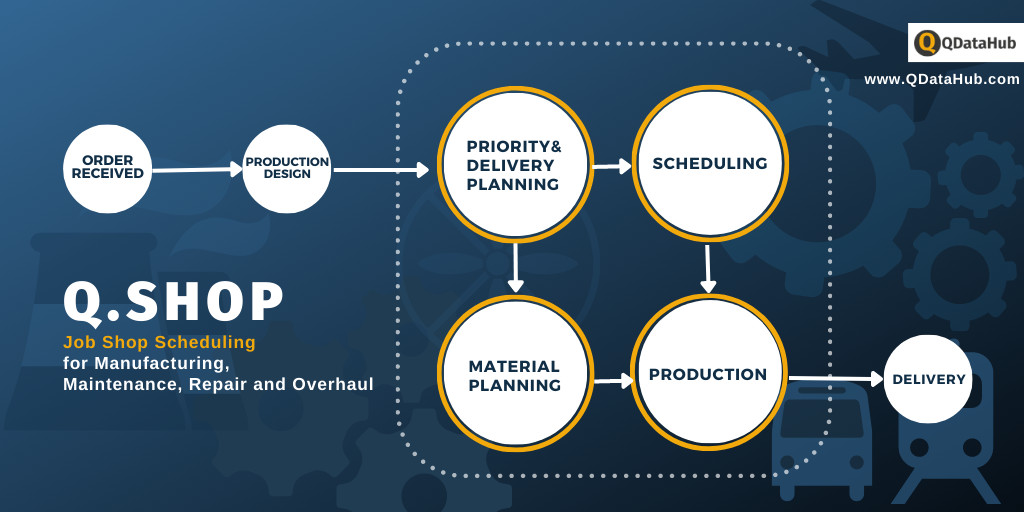

Q.Shop Job Scheduling

Q.Shop Job Scheduler is designed for repair and overhaul and job shop manufacturing. It integrates seamlessly with your existing ERP/MRP. And adds extra functionalities to support operations in the repair and overhaul industries.