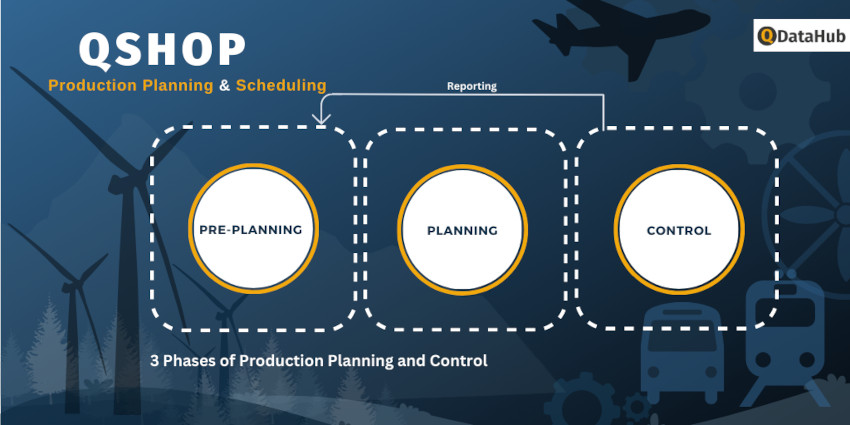

Production Planning and Control in Manufacturing

This article looks at the fundamental principles of Production Planning and Control (PPC).

What are the principles of Production Planning and Control (PPC) in manufacturing? We examine the fundamentals with examples.

Optimize Manufacturing: Automated Production Scheduling

Automated production scheduling handles all the dependencies in production planning and scheduling.

As a result, it simplifies the scheduling process and makes it efficient.

The Power of Master Production Schedule in Manufacturing

A master production plan is part of the manufacturing planning process and reflects sales forecasts.

A master production schedule determines the type and the number of units that should be produced in a timeframe.

Production Scheduling Software for Manufacturing

Production scheduling software enables manufacturing businesses optimize their processes. The right production scheduling software for manufacturing increases throughput and efficiency. Further, it enables businesses to control their labor and equipment costs and lower their overheads.

Maximize Efficiency: Manufacturing Job Scheduling Software

In today’s competitive manufacturing environment, having the right manufacturing job scheduling software means getting ahead in the game. Investing in manufacturing job scheduling software optimizes your manufacturing process.

Finding the best production and planning software is not only about the software. Rather it is about finding the solution that fits your operation the best.

Top 10 questions about production scheduling software

For manufacturing, production scheduling software provides control, accuracy, and visibility over the production schedule. Everything from on-time delivery, customer satisfaction, cash flow, employee productivity, and business continuity all depend on the output of the production planning and scheduling software.

Here are the top 10 features to consider, regardless of the name production scheduling software or manufacturing scheduling software. Hence, Job Shop Scheduling Software is fundamentally different than the two and you should be aware of it.

Manufacturing Scheduling Software: Rising in a Competitive Economy.

In manufacturing, delivering high-quality service takes accurate planning. Manufacturing scheduling software helps businesses make the best use of their resources. It improves production flow and customer satisfaction. Job scheduling streamlines production and maximizes efficiency in manufacturing it maximizes benefits.

A comprehensive scheduling software gives a big picture of production. It also makes production planning faster and more efficient…

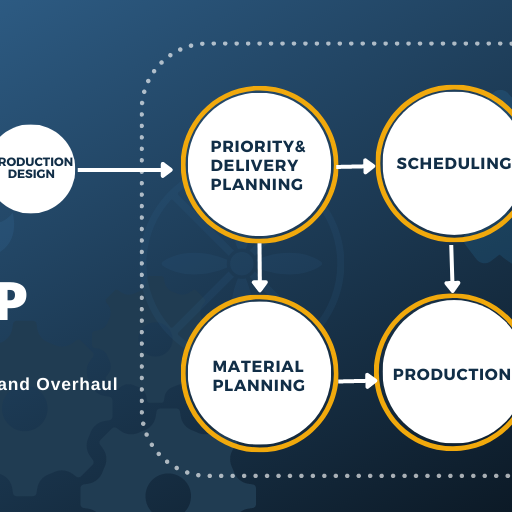

Q.Shop for Job Scheduling

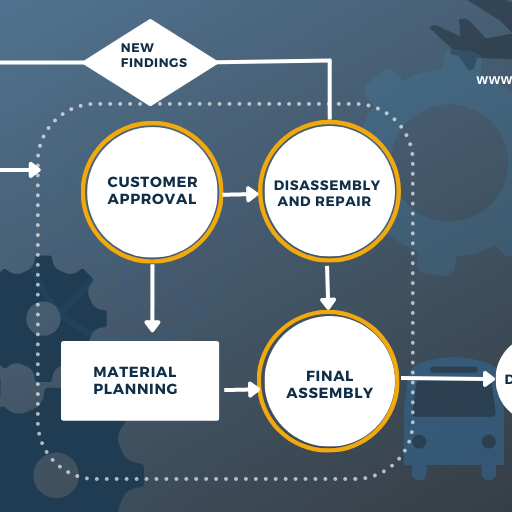

Q.Shop Software offers multiple add-ons for your ERP/MRPs. We help jobs shop manufacturers and repair and overhaul industries to optimize their existing ERP/MRPs to best fit their business models

Q.Shop Job Scheduling handles special care required in repair and overhaul industries. Such as:

- The ability to handle unexpected changes in job requirements, time, and sequences

- The ability to manage small and different batches

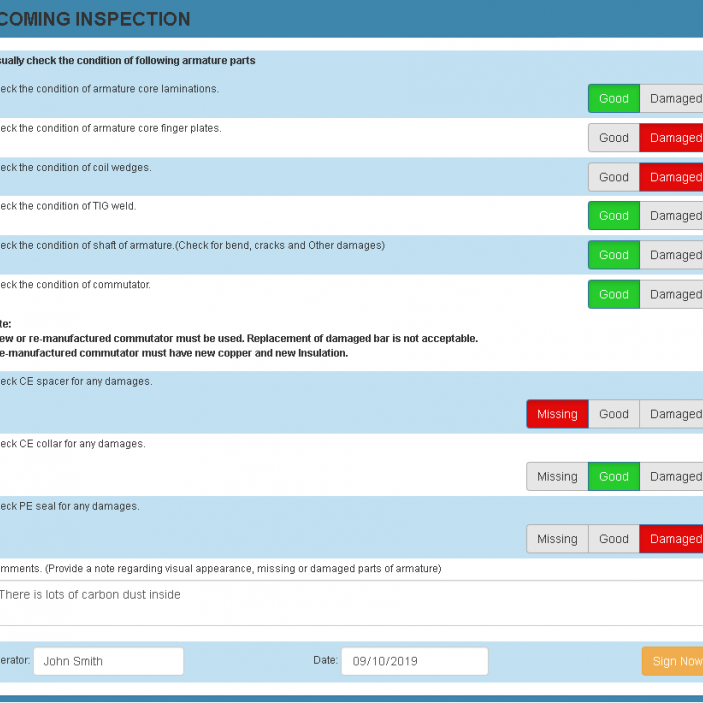

Q.Shop for In-process Inspection

Q.Shop in-process inspection software offers a complete solution to solve challenges on your shop floor.

- The ability for multiple shop employees to work on the same inspection form

- The ability to keep an inspection open as long as required

- Offline save functionality to help your remote service team record their inspection data

CoC meaning in simple language with examples

CoC meaning and its perception vary a lot among different industries and their practical use cases. In short, a CoC is a letter of warranty or a list of specifications for the buyer. Seller issues a CoC to warrant or to show certain specifications.

Conformance VS Compliance

ASA is the acronym for Electro-Mechanical Authority. Their responsibility is to maintain that all manufacturers and mechanical repair shops uphold a safe work environment and quality products while using the best tools available.

All you need to know about Certificate of Conformance

Nowadays, people use Conformance and Compliance in place of one another. Even so, The Certificate of Conformance is a document that guarantees the Conformance of the product to the internally set specifications while the Certificate of Compliance.

Tool Calibration, A Quick Guide.

Tool calibration is the regular maintenance of machines throughout your operation. How do you manage your tool Calibration?

Hold Points

There are certain inspection points that cause a stop in production to be inspected. These kinds of inspections are called hold points and must be inspected by a certain person to ensure quality standards are being met.

First Article Inspection

Tool calibration is the regular maintenance of machines throughout your operation. How do you manage your tool Calibration?

What are Inspections Test Plans? How to create e-ITPs?

All inspections come along with a specific inspection and test report sheet. What do you need to know about creating optimal report sheets while also keeping track of them and which order they are connected to?

EASA Certification

ASA is the acronym for Electro-Mechanical Authority. Their responsibility is to maintain that all manufacturers and mechanical repair shops uphold a safe work environment and quality products while using the best tools available.

In Process Inspection

In-process inspections are considered any type of inspection that takes place after the manufacturing process has already begun. These are usually to check whether compliance is being maintained with ISO 9001 or EASA.

Special Process in ISO 9001

ISO 9001 considers special processes to be any process that has the capacity to change the physical or material elements of the product.

Field Inspection

Gain current insight into your employee’s current work status while they are working remotely. Follow along as they make measurements and observations as they are instantly uploaded to the system.

Inspection Test Report

Inspection Test Report modules are an inspection test checklist for shop floor operations. It tracks your inspection checklist and optimizes the data collection process.

Electronic Production Documents and Reports

With Q.Shop you can give your operators instant access to all production-related documents. Monitor activities on the shop floor in real-time and capture your production data.

Q.Shop ITR Reports

Gain current insight into your employee’s current work status while they are working remotely. Follow along as they make measurements and observations as they are instantly uploaded to the system.

Risk Based Inspection

Inspection Test Report modules are an inspection test checklist for shop floor operations. It tracks your inspection checklist and optimizes the data collection process.

What do you need to know about the Certificate of Compliance (CoC)?

Incoming Quality Control

When thinking of incoming quality control, a simple definition could be: Incoming quality control refers to the procedure that inspects the quality of materials and components that were purchased. This control check is completed before the beginning of production.

ISO 9001: Nonconformity

According to the standards set by ISO 9001, a nonconformity is defined as a failure to meet one or more of the requirements set by a governing body. When a company becomes ISO 9001 certified, it must adhere to a set of regulations and guidelines.

ISO 9001 Certification Process: Cost and Risks

Final Inspection

This inspection takes place during the last stage of the manufacturing process. This inspection determines whether a final product meets the needs of the customer and the product requirements set.

Field Inspection

Access your off-site work in progress from anywhere, through workstations, touchscreen monitors, or mobile devices. Bring your field job inspection paperwork to your fingertips and eliminate delays, after-hours data entry, double data entry, and the pain of reading handwritten scribbles.

Expediting Delivery and Order Follow Up

Document Control and Management

One unique, simple, and easy-to-use interface addresses all concerns around document control with much more added functionality.

Q.Shop for Repair and Overhaul

Electronic Inspection Test Plans (eITP), Job Shop Scheduling