Inspection Test Report modules are an inspection test checklist for shop floor operations. It helps you track your inspection checklist, and access all production documents and reports needed to complete your jobs.

Q.Shop’s ITR module automates all your Inspection Test Report documents and puts them all in one accessible and easy to use platform.

What an Electronic Inspection Test Report system can do?

ITR for Data Collection

With Q.Shop’s ITR module, you can capture and store Inspection Test Report (ITR) or Inspection and Test Plan (ITP) information.

Furthermore, it makes your data entry process quick and easy by giving you features such as colour-coded data buttons, voice to text data entry, automated pass and fail, as well as embedded logic and calculation capabilities.

Plus, using online inspection forms, operators can directly access all their production procedures and related documents. Further, the embedded document manager and control make sure that employees can see the current/valid version of all documents and instructions.

ITR for production managers

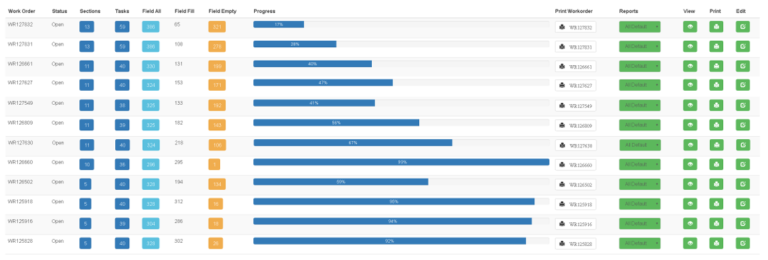

The ITR module helps the management team to get a real-time view of the operation and monitor and measure activities on the shop floor. Production managers and supervisors also have access to various ITR reports. These production reports help them to get a holistic view of the operation helping them to make better and faster decisions about the operation.

An electronic Inspection and Test Report can help you:

Q.Shop can help you streamline your inspection process, so you can sustain the quality of your products and optimize your production.

Handling off-site jobs

Many operations are forced to use paper forms to enter their ITR inspection data. One reason could be having to do various off-site inspections. For example, inspecting a train or turbine requires an off-site inspection and as a result a paper-based process. This translates to double data entry at the end of the day.

Q.Shop’s ITR solution is born out of a real need in the industry. Using Q.Shop software, your remote or off-site team can seamlessly access the inspection forms and related instructions. Furthermore, your office team can see a live progress feed of the off-site inspection and instant communication with the inspector.

Handling several different ITR forms

Having to deal with many inspection forms is another reason why many operations are still forced to rely on paper. In an MRO (Manufacturing Repair and Overhaul) type of operation, this is a common case.

Since every customer and vendor requires their own set of inspection and test report forms, no single system can fit all those different needs. As a result, you end up printing the customer’s excel file and circulating it on the shop floor. Only to scan the result, or reenter the data to return back to your customers.

We’ve designed our solution to address industries that have to deal with hundreds of different inspection forms. Q.Shop will brings all your existing paper forms together under one Inspection and Test Report system.

Top 9 ways that an automated inspection test report system can help you.

1- It gives you real-time access.

You don’t need to wait until the end of the day to get job progress documents from operators. Instead, have real-time insight into the progress of ongoing jobs.

Your management and executive team have instant access to work order progress from all sections of your process.

2- It improves your customer service.

You can provide accurate quotes and live updates to your customers. Further, you can do this without the need to ask shop supervisors or production planners for that information.

3- It minimizes errors.

The effective interface design in Q.Shop ITR system minimizes data entry errors and streamlines the data entry process. These include colour-coding to identify faulty inspection points and more.

4- It makes data-entry fast.

It makes your data entry much faster. Features such as automatic pass/fail, automatic formula/logic, speech to text data entry, bar code scanning, and direct photo uploads to shorten your data entry time and improve the data being entered.

5- It makes communication easy.

Q.Shop’s inspection test Report Report system bridges the communication between engineering, quality, customer service and the management team.

You gain insight into your company-wide performance by creating seamless communication between your shop floor operators, your field operators and your office.

You can manage more work in progress and rectify issues in the production flow. At the same time, you give shop technicians the confidence to communicate effectively with their managers.

6- It makes quoting accurate.

Your customer service and sales teams can provide much more accurate quotes and production updates to customers. This can be done right from their desk, with information being collected by the system.

7- It gives your team insight.

The transparency of shop floor information gives insight into the progress of jobs. Further, various ITR reports give you extra tools to see your progress over time and aid your teams’ decisions when making changes.

8- It expedites your production.

Your internal shop technicians and the remote teams can back-order parts from the job site. This, in turn, expedites the process of completing outstanding service jobs.

9- It manages all your other documents.

Having to circulate the latest version of drawings, work instructions and manuals can become cumbersome in a shop floor environment. That’s why Q.Shop’s embedded document management system can greatly improve your overall operational efficiency.

With our inspection and test report system, you access the latest version of maintenance instructions and technical manuals. Besides, your engineering team and shop operators can collaborate on forms and share the latest version of instructions with the touch of a button.

Simplifying Quality Inspection.

Measure, monitor, and manage quality data throughout the production cycle or repair and overhaul process. We offer production workforce management and document management solutions.