For manufacturing, production scheduling software provides control, accuracy, and visibility over the production schedule. Everything from on-time delivery, customer satisfaction, cash flow, employee productivity, and business continuity all depend on the output of the production scheduling software.

The name production scheduling software is more suitable to cover the production of industries like line manufacturing, job shop manufacturing, and repair and overhaul service providers.

Here are the top 10 features to consider, regardless of the name production scheduling software or manufacturing scheduling software. Hence, Job Shop Scheduling Software is fundamentally different than the two and you should be aware of it.

Here are the questions covered in this guide:

- Why is job shop scheduling difficult?

- Why customer approval is important in production scheduling software?

- Why do you need scheduling flexibility on job priorities and business objectives?

- What is the importance of labor in Job Shop Scheduling?

- Why time is of the essence for running Production Scheduling software?

- What is the difference between a job shop and a line production?

- What is the overhead of administrating and maintaining the Scheduler software?

- How does a flexible job shop scheduling software adapt to your business?

- What do you need to know about management visibility and reports?

- What is the limitation on data or their value in production and planning software?

1. Why is job shop scheduling difficult?

Job shop manufacturing is different from the mass production line.

Manufacturing processes vary from one order to the next, and to make it worse, most orders are for a quantity of one or small batches.

The job shop scheduling is more difficult as it manages production output with consideration of available resources, material availability, deadlines, cash flow, customer demand, and other business objectives.

This type of production scheduling is popular among Make To Order (MTO), Maintenance, repair and overhaul (MRO), Custom Manufacturing, Repair Shop, Machine Shop, and more.

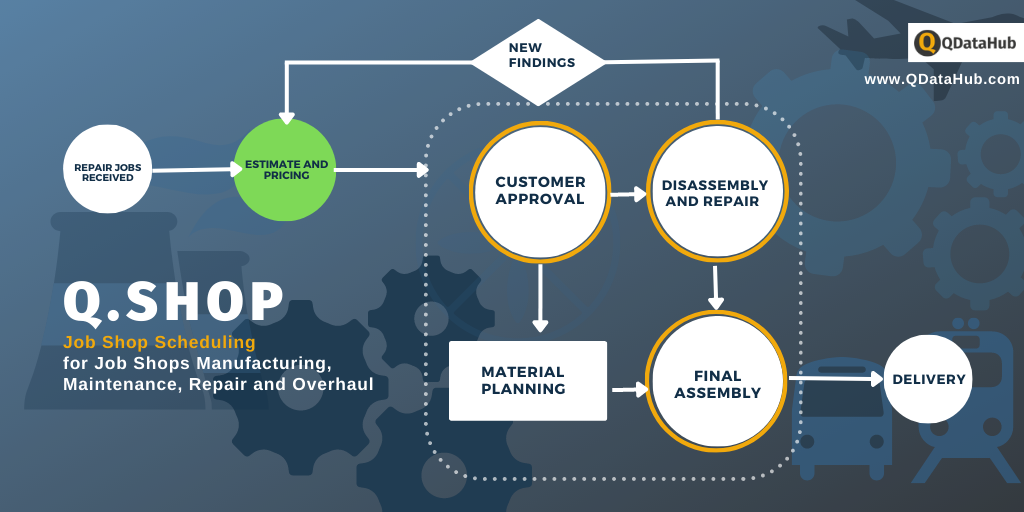

2. Why customer approval is important in production scheduling software?

The sales cycle of a job shop becomes complex as customer approval is needed for any new finding or extra necessary work. This approval process adds up to the complexity of the production process as materials are not ordered ahead of time.

The customer order spends a lot of its life cycle in the stage of waiting for approval or waiting for material. Hence taking space and production resources.

A Job Shop Scheduling software provides better resource utilization and higher production throughput.

When a material with a long lead time arrives; it will make an influx of orders available to resume production. Q.Shop Scheduler natively supports such phenomenon of the job shop environment.

3. Why do you need scheduling flexibility on job priorities and business objectives?

Each customer is important and should receive their products. At the same time, every business has certain objectives and targets that are vital to its operation.

Some sales targets must be achieved to support the cash flow of the company. Some customers need to keep happy as they are the source of continual revenue for the company.

Q.Shop Scheduler Software provides an unlimited combination of defining these objectives.

4. What is the importance of labor in Job Shop Scheduling?

The labor in job shop scheduling identifies as the main constraint. In a job shop environment, production is mainly carried out by the labor force, their capabilities, and their availability.

The contrary to a production line is that the majority of the work is done by machinery, robots, and automatic arms. Here are two important differences to consider:

- In line manufacturing, production flow is predefined and arranged well ahead of time.

- In the production line, the labor is more of a monitor or a machine operator who can easily switch places.

Q.Shop Resource Scheduler provides the most possible functionalities for managing human resources.

5. Why time is of the essence for running Production Scheduling software?

Job shop manufacturing has a very highly volatile production environment. Usually, there is no redundancy for machinery because of cost or their specialties.

So all of a sudden a piece of machinery break down and every schedule for the day should change. This makes it very important how quickly you can reschedule the shop to reduce lost time.

A full run of Q.Shop Scheduler takes less than a minute. So you are back to the value-added time in no time, instead of waiting for hours to get a new schedule.

6. What is the difference between a job shop and line production?

In mass production line tasks and their timing are arranged in a positive and forward fashion. Putting a cover with 10 bolts gets scheduled for 10 minutes.

The job will be considered as done and moves to the next operation even if only 9 bolts were available. The job is theoretically 90% done but practically 100% done as the cover is on. They mark the unit with a red tag for missing bolts when the bolt becomes available.

If the job shop production schedule has a hiccup, it will domino effect on the rest of the production. But on the other side taking the cover off is a bit different.

You may allocate twice the time for opening bolts and schedule the job for 20 minutes, to have some buffer in case something goes wrong.

Yet if one bolt breaks and does not come off, you cannot move the job to the next operation. The job is theoretically 90% done but from the perspective of the next operation, it is 0% done as the cover still is there.

So the next operation cannot start and the job has to wait as the cover is still on.

This delay and the waiting period will push successive operations as the result. This ripple effect is costly depending on when it happens and the number of successive operations.

The right production scheduling software can remove unexpected delays. Q.Shop Scheduler provides different means of configuring and handling such dilemmas.

7. What is the overhead of administrating and maintaining the Scheduler software?

Your report is good as your data. Garbage in, garbage out. Pay me now, or pay me later. There is no shortage of mantras or slogans on this subject. It is a fact that any system needs administration to operate, but the question is how much.

Maintaining a scheduler system is an ongoing administration activity. And it is a none value added effort toward the final product. So it is a no-brainer that the lower the overhead higher the profit. At the same time, with no administration, there will be no sales.

Here are the two major administration overhead when a shop scheduler:

1- Daily and routine administrations

In a production environment, some administrative works are necessary. This is regardless of having a computer system in place, using pen and paper, or simply managing it in your brain.

This is the list of daily administrative tasks that you need to track on a job shop:

- Inventory Level: You need to keep track of your material in and out as it happens to maintain the inventory level.

- Work Progress: You need to update your work progress status, to know how far the job is done.

- Equipment Availability: You need to somehow track if a piece of equipment is going o be down for maintenance purposes or if gets broken.

- Human Resources: You need to have a list of employees and their capabilities or their skill matrix.

- Purchase parts and services: You need to manage purchased material, and the subcontracted component arrival time.

2- One-time setup and configuration of the production scheduling software

Certain information is about how you operate or produce a product. The administration of such information is a One-time setup and is for the configuration of the product.

- Materials: What parts and raw materials do you need for the job?

- Tasks: What are the production activities for the job?

- Equipment: Which machinery and equipment is used for the job?

- Capabilities: Which skill levels or capabilities should work on the job?

You will build a library of such product development along the path as you make them for the first time. But the system will keep and use them for the next time around.

Note: Integration is the key to lowering the administration cost in implementing production scheduling software

Maintaining all such information for the scheduler system is a big burden. But a smart scheduler that integrates into the system can have zero overhead. A well-integrated scheduler will pick up the required information from their source.

For example, purchase orders are already in a system and there should be no need for double entry. Q.Shop Scheduler offers full integration which translates to zero overhead.

8. How does a flexible job shop scheduling software adapts to your business?

The system works perfectly if you change it a little bit differently than how you are working now. Most likely, you have heard this before. Isn’t it supposed to be the other way around?

The production scheduling software should provide enough flexibility and options to adapt to your business, not forcing you to change your processes.

A configurable scheduler adapts to your business versus you trying to work according to the software. The ability to configure or customize the scheduler will reduce the training time and expedite the go-live.

It also contributes to the success of the project as there is less shock to the whole system. As a result, employees will buy into the new scheduler system easily.

9. What do you need to know about management visibility and reports?

The main purpose of a scheduler system is to orchestrate the production according to a plan. Yet it should provide solid and trustworthy insights to management. Time is money, and information is power.

Q.Shop scheduler reports are easy to understand and follow. These reports provide live insights into your production to support your management decision-making. Every level of management deals with different decision-making activities and responsibilities.

For each manager, reports summarize the information according to their needs. Sales managers can see if orders are on time or going to be late much ahead of time. So they have enough time to react. Business owners can decide on capital investment for extra machinery or human resource.

10. What is the limitation on data or their value?

Looking for production scheduling software you need to make sure that the software places no limitations on your manufacturing process. Examples of such limitations could be:

- Limitation on the number of shifts per day.

- Limitation on the definition of the work week for all employees.

- Limitation in defining the number of resources per task

- Limitations on the size of the data

- Limitation on the number of orders

- limitation on the number of resources per order

We understand the dynamic needs in the repair and overhaul manufacturing (MRO) and job shops. as a result Q.Shop job Scheduler places no limitation on data or their value and offers unlimited options for all. Q.Shop production scheduling software offers unlimited shift patterns per day, per week, and per employee, and be flexible as you need.

We hope you

Q. Shop Production Scheduling Software

Q.Shop Production Scheduling Software helps job shop manufacturing and repair and overhaul businesses, MRO, with Job Scheduling, Automated Scheduling, and Scheduling Dynamic Changes.